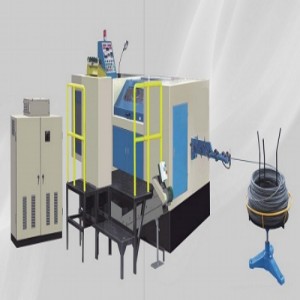

Description

Salient Features

The latest design, beautiful appearance, high speed, high efficiency, low energy consumption, easy to operate.

Important components, such as bed and sliders are made of high strength and quality castings, and high stability.

Guide plate and crankshaft uniform imported high wear resistance alloy steel, and after special treatment, super wearable.

The main slide rails design adopts before and after (double track) designed to ensure high-speed impact, stable and reliable.

The new type cam and lifter system to ensure the accuracy of first and second punching stability.

Some parts adopts machining center to ensure the accuracy and interchangeability of parts.

Oil tank multi-stages filtration,forced circulation lubrication system to ensure that the oil filtered and clean to the lubrication points which can extend equipment life.

Suitable for making of small screws, precision screws, extra long screws.

Main Technical Parameters

| Parameters | Unit | |

| Max.Diameter | mm | 5 |

| Max.Length | mm | 50 |

| Main slider stroke | mm | 81 |

| Speed per Min. | pcs | 140-160 |

| Main mould outer dia. | mm | 34.5 |

| Cutting mould outer dia. | mm | 19 |

| First punch die ourter dia. | mm | 31 |

| Second punch die ourter dia. | mm | 31 |

| Motor power | KW | 3.0 |

| Crank axle dia. | mm | 71 |

| Bearing bush dia. | mm | 70 |

| Dimension | MXMXM | 2.1*1.1*1.2 |

| Weight | KG | 1700 |