Description

WHAT’S COLD ROLLING?

Rolling is the term used to designate forming (generally cold) of a round part (cylindrical or tapered) by tools, rotating or otherwise, in various numbers and arrangements around the work-piece.

Forming can also be carried out at medium temperature on certain materials (in the aeronautical industry in particular). Rolling is used increasingly because it brings many advantages compared with machining:

- Improved surface condition (which can be further improved by burnishing).

- Increased mechanical strength by work hardening (see below), by avoiding fracture starts generally due to tool marks or scratches and by fibring obtained on rolling.

- Economy of matter since the blank diameter (the one whose volume corresponds to that of the finished part) is less than that of the finished part (outer diameter).

- Shorter cycle time on machining in many applications (above all on spline rolling).

- Better quality is achieved than with conventional machining: rolling is therefore occasionally used to obtain a better quality than machining and to avoid milling.

TOOLS

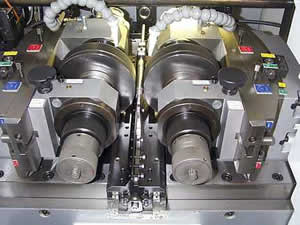

There are generally two tools, but one, three or four tools are also regularly used (even more in certain cases). The reason for increasing the number of tools is to reduce the force applied locally to the workpiece in order to avoid deforming it too much (for instance, a hollow part). The tools are generally arranged symmetrically around the workpiece (except in the case of a single tool) to avoid stress on holding the workpiece, and maintains the workpiece in the centre of the tools (no radial movement of the workpiece during forming, an important factor when working long bars or heavy items, for instance).

There are three possible tool shapes:

- Convex: the tools have a circular form with an outer active surface.

- Straight: these are usually called rack or die stock.

- Concave: the tools have a circular shape but with an inner active surface.

HOW IT WORKS

The tool has one (or several) relief profiles and is driven in rotation. Contact between the tool and the workpiece drives the latter in rotation and a mirror profile of the tool is progressively impressed on the workpiece through the force applied to the tools and the variable profile of the tool. Between two tool profiles, the part material is displayed to form the outer diameter of the profile. This displacement is parallel to the surfaces in contact between the tool and the workpiece. It flows all the more easily as the angle between the tool and workpiece contact surfaces and the direction of the force (or the variation of profile) approaches 90°. If not used to develop a profile, displacement of the material can be used to tie two parts. This operation consists of crimping. The tie can be either in translation or in rotation with or without leaktightness between the two workpieces. Certain rolling operations are designed only to create a surface finish on the workpiece or to calibrate a particular shape. In this case, there is no or very little displacement of the material. This is called burnishing or finish rolling (in particular used for the pinions of gear boxes to avoid costly operations such as shaving, grinding or honing).

The rolling cycle breaks down into three parts:

- Penetration: The tool is brought to the workpiece and presses against it either to “print” its profile on the previously smoothed blank, or for burnishing or calibrating the surface.

- Calibration: The workpiece is made round, which is not the case momentarily during penetration.

- Decompression: The tool and the workpiece move apart in order to free the workpiece and machine elasticities. This phase ultimately makes a workpiece circular or otherwise. Failed decompression will induce a “signature” in the part, which is no longer round (visible on measuring its circularity).

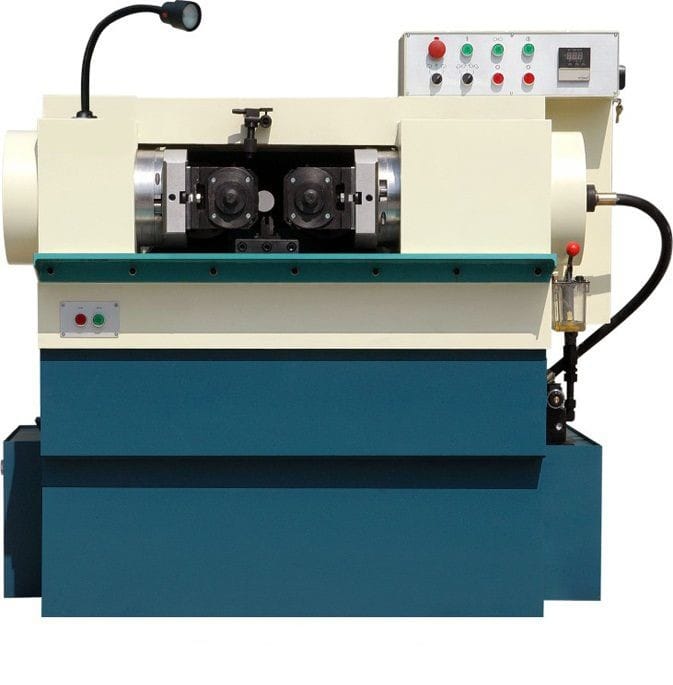

Driven by a hydraulic system, oil cylinder at right side of the machine operates to roll workpieces at radial or axial directions; the machine is structured by a cast frame for high stiffness and precision.

Economic, wider application, especially for processing of all kinds of threads, endless screws of small modulus, or knurling, barreling and straightening.

Main Technical Parameters

|

APA28-15 Thread Rolling Machine

|

|||||

| Max. rolling pressure | KN | 150 | |||

| Rolling thread range | Max. diameter | Radial feed | mm | 60 | |

| Axial feed | mm | 45 | |||

| Max. pitch | Radial feed | mm | 4 | ||

| Axial feed | mm | 5 | |||

| Rolling die range | Max. outer diameter | mm | 178 | ||

| Aperture | mm | 54 | |||

| Max. width | mm | 120 | |||

| Max. center distance btw. main axis | mm | 240 | |||

| Main axis rotation | r.p.m. | 28.35.45.56 | |||

| Main axis inclination |  |

||||

| Feed travel | mm | 0-12 | |||

| Center height | mm | 900 | |||

| Gross power | KW | 7,2 | |||

| Dimensions (L*W*H) | mm | 1500*1440*1400 | |||

| Packing dimensions (L*W*H) | mm | 1800*1750*1900 | |||

| Kg | 2500 | ||||