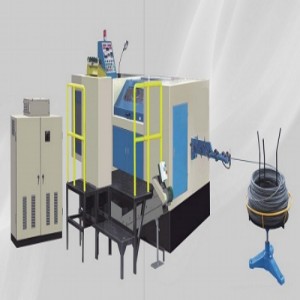

Description

Busbar metal belt material straighten leveling machine Specifications

| MODEL | UNIT | AKS-SL-160 | AKS-SL-260 |

|---|---|---|---|

| MAX.PROCESS MATERIAL WIDTH | MM | 160 | 260 |

| PROCESS MATERIAL THICKNESS | MM | 3 TO 12 | 3 TO 12 |

| LEVELING ROLLER QUANTITY | PCS | 13 | 13 |

| ROLLERS ROTARY SPEED | RPM | 34 | 34 |

| LEVELING ROLLER LINEAR SPEED | MM/MIN. | 6500 | 6500 |

| LEVELING ROLLER DIAMETER | MM | 90 | 100 |

| LEVELING ACCURACY | MM/M | <1 | <1 |

| MOTOR POWER | KW | 3 | 5.5 |

| WEIGHT | TON | 0.7 | 1.2 |

| DIMENSIONS | CM | 125*80*115 | 135*100*125 |

Busbar metal belt material straighten leveling machine Applications and Features

Application: The equipment has the functions of straight and levelling the metal belt material for making brass busbar and aluminum bus bar.

Features:

1.This machine is a roller-type leveling machine with high output speed, high efficiency, no installation, simple and convenient operation, and can be used with bus processing machines. This machine adopts curvature compensation technology. Compared with the traditional roller effect leveling, the phenomenon of workpiece slippage is improved, the force is reasonable, the electric energy saved half, and the service life of the machine is greatly extended.

2.This machine adopts the chain transmission method, replacing the traditional gearbox and connecting rod. Simple structure, stable work, high efficiency and convenient maintenance.

3. Adopt two-hand wheel adjustment method, convenient and quick.

4.The 13-roller structure and dual power are used to effectively improve the slippage of the workpiece, which saves electricity and ensures the surface quality of the workpiece.