Description

CNC Busbar Shape Bending and Forming Machine Specifications

| MODEL | UNIT | AKS-OB400 |

|---|---|---|

| MAX. PROCESS ANGLE | DEGREE | 90 |

| BENDING PROCESS SIZE(FLAT) | MM | 200*15 |

| BENDING PROCESS SIZE(VERTICAL) | MM | 125*15 |

| BENDING ACCURACY | DEGREE | ±0.3 |

| FORCE POWER | KN | 400 |

| MAIN MOTOR POWER | KW | 7 |

| BENDING MAX. STROKE | MM | 250 |

| SIDE MATERIAL BLOCK STROKE | MM | 2000 |

| SIDE MATERIAL BLOCK MAX. SPEED(X AXLE) | M/MIN. | 15 |

| BENDING AXLE MAX. SPEED(Y AXLE) | M/MIN. | 5/1.25 |

| MIN. U SHAPE BENDING WIDTH | MM | 40 |

| DIMENSIONS | CM | 445*149*100 |

| WEIGHT | TON | 2.7 |

CNC Busbar Shape Bending and Forming Machine Applications and Features

Application:Be used to bend the shapes of Busbars , such as flat strips, solid bars, or rods, and are typically composed of copper, brass, or aluminium as solid or hollow tubes.

Features:

1.With functions of various shape bus bar forming.

2.NC bus bar bending machine is a computer-controlled bus bar bending processing special equipment. The X-axis and Y-axis movements cooperate with each other to manually feed materials to complete various bending actions. Selecting different molds can complete the process of plane bending and side bending of the busbar. This machine can be used in conjunction with 3D software. The software can accurately calculate the bending unfolding length for workpieces with a large number of bending times. It can automatically find the bending sequence, and realize programming automation to simulate the bending process. Place the busbar according to the simulated bending sequence. Avoid incorrect bending position.

3.Closed bending structure: X and Y axes use precision linear guides to ensure processing accuracy, avoid the disadvantages of open bending, and ensure that the processing angle is consistent in the width direction: when bending, the machine mold has automatic clamping and release Function, to ensure the flatness of the processing plane.

4.Touch screen: human-machine interface, simple operation, real-time reflection of program running status, with display device operation alarm information function, can easily set mold parameters and operate equipment operation.

5.High-speed running system: The machine uses high-precision ball screws and linear guides to ensure that high-precision and high-efficiency. Components are well-known brands with long service life and guaranteed quality.

CNC Busbar Shape Bending and Forming Machine Structure and Components

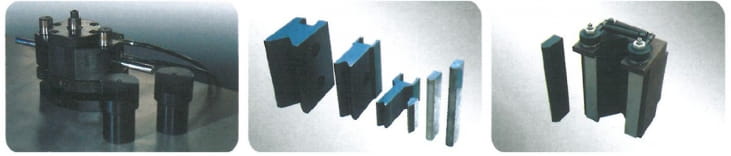

CNC Busbar Shape Bending and Forming Machine Bending Die and Shaping Mold

CNC Busbar Shape Bending and Forming Machine Produced Busbar Samples

1.Sheared bus bar plate 2.Standing bend and twisted bus bar 3.Holes punched bus bar 4.U shape bending bus bar 5.Holes punched and knurling pressed bus bar 6.8.Punch and bend combination bus bar 7.Twisted bus bar